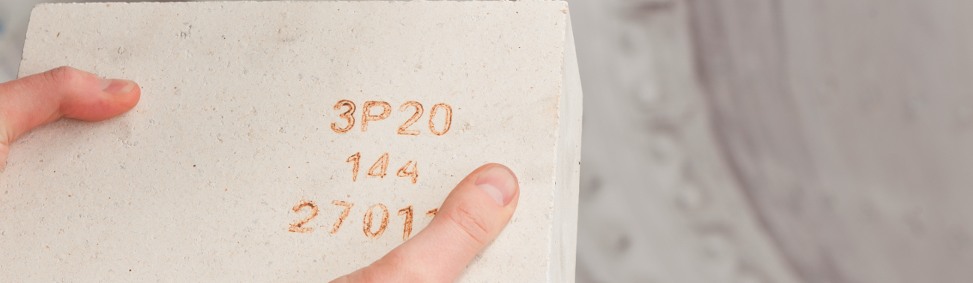

Dense Shaped Refractory products

Refractory bricks have specific shapes and are in majority fired at high temperatures to form a ceramic bond. The raw material mixture, type of compaction and the heat treatment determine the final properties of dense shaped refractory materials.

More than 50% of all shaped refractory products can be allocated in a chemical / mineralogical sense to the binary system SiO2 - Al2 O3 . In general, with increasing Al2 O3 content also the refractoriness and maximum application temperature of the brick increases. But, depending on the raw materials used, accompanying substances (impurities) such as Fe2 O3 , TiO2 , alkalies, earth alkalies can have a significant influence on the final properties by the formation of low melting phases.

Synthetic high alumina materials provide stable chemical compositions with low amount of impurities and allow the formulation of high performing refractory bricks with reliable properties.

read more

Tabular & other Aggregates

Spinel AR 78

Alumina-rich spinel (78% Al 2 O 3 ) Used for steel ladle shapes and monolithics

Alumina-rich spinel (78% Al 2 O 3 ) Used for steel ladle shapes and monolithics

GP-004_Magnesium_Aluminate_Spinel_0224 62 KB

( en )

2019 - Formation of Hexa-Aluminate Solid Solution Phases in Spinel Containing Castables

( en )

2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties

( en )

2016 - Value Enhancement Through Engineered Alumina Products For Monolithic And Brick Applications

( en )

2013 - Castables for Industrial Applications – Still Room for Improvement!

( en )

2012 - Rheology of High Performance Alumina and Spinel Castables

( en )

2010 - Spinel: in-situ versus preformed- clearing the myth

( en )

2008 - Latest Development in Refractory Monolithics

( en )

2005 - Raw material concepts for SiO2 free high strength and low wettability aluminium castables

( en )

2004 - Magnesium Aluminate Spinel Raw Materials for High Performance Refractories for Steel Ladles

( en )

2002 - Raw material concepts for SiO2 free high strength castables in the temperature range up to 1200°C

( en )

1994 - The influence of SiO2 and Spinel on the hot properties of high alumina low cement castables

( en )

1992 - New Sinter Spinels for Castables in Steel Applications

( en )

close

Calcined Aluminas

CT 9 FG

for refractory matrix enhancement Particle size / D50 = 3.5µm Na 2 O Content = 0.15%

for refractory matrix enhancement Particle size / D50 = 3.5µm Na 2 O Content = 0.15%

RP-EU_RCP_007_Calcines_and_Reactives_for_Refractories_0224 482 KB

( en )

2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties

( en )

2012 - Rheology of High Performance Alumina and Spinel Castables

( en )

2011 - Review of Matrix Aluminas for Refractory Formulations

( en )

2002 - Upgrading Castable Performance through Matrix Optimization

( en )

1983 - Fine Aluminas for High Performance Refractories

( en )

close

A 2 -325

Alpha-alumina for refractory matrix enhancement Particle size / D50 = 5.5µm Na 2 O Content = 0.30%

Alpha-alumina for refractory matrix enhancement Particle size / D50 = 5.5µm Na 2 O Content = 0.30%

close

CT 800 FG

Alpha-alumina for refractory matrix enhancement Particle size / D50 = 3.5µm Na 2 O Content = 0.12%

Alpha-alumina for refractory matrix enhancement Particle size / D50 = 3.5µm Na 2 O Content = 0.12%

RP-EU_RCP_007_Calcines_and_Reactives_for_Refractories_0224 482 KB

( en )

RP-EU_006_Calcines_and_Reactives_for_Ceramics_0224 412 KB

( en )

GP-018_Global_Aluminas_for_Refractories_Applications_0224 44 KB

( en )

2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties

( en )

2012 - Rheology of High Performance Alumina and Spinel Castables

( en )

2011 - Review of Matrix Aluminas for Refractory Formulations

( en )

2002 - Upgrading Castable Performance through Matrix Optimization

( en )

1983 - Fine Aluminas for High Performance Refractories

( en )

close

CT 10 SG

Special alumina for gunning applications Particle size / D50 = 3.0µm Na 2 O Content = 0.4%

Special alumina for gunning applications Particle size / D50 = 3.0µm Na 2 O Content = 0.4%

RP-EU_RCP_007_Calcines_and_Reactives_for_Refractories_0224 482 KB

( en )

RP-EU_020_High-Surface_0224 41 KB

( en )

2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties

( en )

2012 - Rheology of High Performance Alumina and Spinel Castables

( en )

2011 - Review of Matrix Aluminas for Refractory Formulations

( en )

2002 - Upgrading Castable Performance through Matrix Optimization

( en )

1983 - Fine Aluminas for High Performance Refractories

( en )

High Performance Gunning Mix with Alumina Plasticiser

( en )

close