Reactive Aluminas

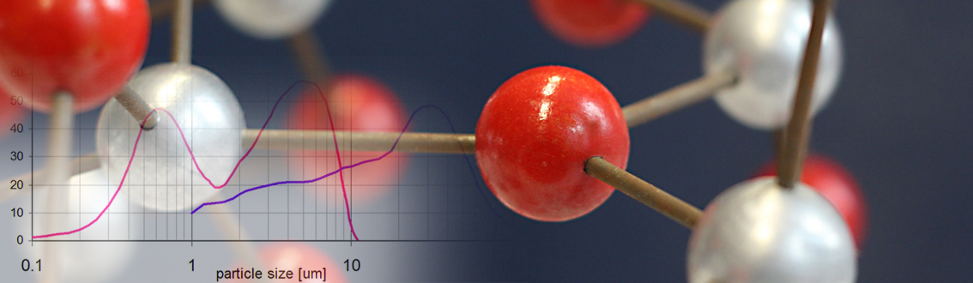

Reactive aluminas are specially designed for the production of high performance refractories where defined particle packing, rheology and consistent placement characteristics are as important as the superior physical properties of the final product. Reactive aluminas are fully ground down to the primary (single) crystals by highly efficient grinding processes. The average particle size, D50, of mono-modal reactive aluminas, is therefore nearly equal to the diameter of their single crystals. The combination of reactive aluminas with other matrix components, such as tabular alumina 20μm or spinel 20μm, allows the control of the particle size distribution to achieve the desired placement rheology.

Almatis has the broadest reactive alumina product portfolio available around the globe, with products from sub-micron to 3 micron particle size. Particle size distributions, ranging from mono-modal to bi-modal and multi-modal, allow full flexibility in formulation design and provide the convenience of co-milled engineered reactive aluminas.

Mono-modal alpha-alumina

Particle size / D50 = 0.6µm

Na2O Content = 0.08%

Mono-modal alpha-alumina

Particle size / D50 = 0.6µm

Na2O Content = 0.08%

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Mono-modal alpha-alumina

Particle size / D50 = 1.8µm

Na2O Content = 0.12%

Mono-modal alpha-alumina

Particle size / D50 = 1.8µm

Na2O Content = 0.12%

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2005 - Raw material concepts for SiO2 free high strength and low wettability aluminium castables ( en )

- 2002 - Raw material concepts for SiO2 free high strength castables in the temperature range up to 1200°C ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Mono-modal alpha-alumina

Particle size / D50 = 3.3µm

Na2O Content = 0.23%

Mono-modal alpha-alumina

Particle size / D50 = 3.3µm

Na2O Content = 0.23%

- RP-AM_RCP_045_Calcines_and_Reactives_for_Refractories_0224 488 KB ( en )

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Bi-modal alpha-alumina

Particle size / D50 = 2.5µm

Na2O Content = 0.10%

Bi-modal alpha-alumina

Particle size / D50 = 2.5µm

Na2O Content = 0.10%

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Bi-modal alpha-alumina

Particle size / D50 = 2.5µm

Na2O Content = 0.10%

Bi-modal alpha-alumina

Particle size / D50 = 2.5µm

Na2O Content = 0.10%

- 2017 - Comparison of Cement- and Hydratable Alumina-Bonded Alumina-Spinel Materials for Steel Ladle Purging Plugs ( en )

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Bi-modal alpha-alumina

Particle size / D50 = 1.4µm

Na2O Content = 0.08%

Bi-modal alpha-alumina

Particle size / D50 = 1.4µm

Na2O Content = 0.08%

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Multi-modal alpha-alumina; low dilatancy

Particle size / D50 = 1.7µm

Na2O Content = 0.20%

Multi-modal alpha-alumina; low dilatancy

Particle size / D50 = 1.7µm

Na2O Content = 0.20%

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2010 - Technical and economic review of high alumina raw materials for steel refractories ( en )

- 2009 - E-SY Alumina for easy to use high-performance castables ( en )

- 2004 - E-SY Pump - The new solution for pumpability of silica free high performance tabular alumina and spinel castables ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Multi-modal alpha-alumina

Particle size / D50 = 1.5µm

Na2O Content = 0.08%

Multi-modal alpha-alumina

Particle size / D50 = 1.5µm

Na2O Content = 0.08%

- RP-EU_RCP_007_Calcines_and_Reactives_for_Refractories_0224 482 KB ( en )

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2005 - Raw material concepts for SiO2 free high strength and low wettability aluminium castables ( en )

- 2002 - Raw material concepts for SiO2 free high strength castables in the temperature range up to 1200°C ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Multi-modal alpha-alumina

Particle size / D50 = 1.5µm

Na2O Content = 0.16%

Multi-modal alpha-alumina

Particle size / D50 = 1.5µm

Na2O Content = 0.16%

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1996 - The Matrix Advantage system, a new approach to low moisture LC selfleveling alumina and alumina spinel castables ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Multi-modal alpha-alumina; spinel containing

Particle size / D50 = 1.6µm

Na2O Content = 0.10%

Multi-modal alpha-alumina; spinel containing

Particle size / D50 = 1.6µm

Na2O Content = 0.10%

- RP-EU_RCP_007_Calcines_and_Reactives_for_Refractories_0224 482 KB ( en )

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2005 - Raw material concepts for SiO2 free high strength and low wettability aluminium castables ( en )

- 2002 - Raw material concepts for SiO2 free high strength castables in the temperature range up to 1200°C ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1996 - The Matrix Advantage system, a new approach to low moisture LC selfleveling alumina and alumina spinel castables ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Multi-modal alpha-alumina; low dilatancy;

Particle size / D50 = 1.4µm

Na2O Content = 0.10%

Multi-modal alpha-alumina; low dilatancy;

Particle size / D50 = 1.4µm

Na2O Content = 0.10%

- RP-EU_RCP_007_Calcines_and_Reactives_for_Refractories_0224 482 KB ( en )

- 2016 - Case Studies on Optimization of Selected Value-added Premium Aluminas to Attain a Comprehensive Leap in the Refractory Properties ( en )

- 2012 - Rheology of High Performance Alumina and Spinel Castables ( en )

- 2011 - Review of Matrix Aluminas for Refractory Formulations ( en )

- 2002 - Upgrading Castable Performance through Matrix Optimization ( en )

- 2001 - Responding to the refractory industry's need for fully ground matrix aluminas ( en )

- 1983 - Fine Aluminas for High Performance Refractories ( en )

Ground Median Size = 2.7µm

Ground Surface Area = 2.5 m²/g

Na2O Content = 0.30%

Ground Median Size = 0.6µm

Ground Surface Area = 8.2 m²/g

Na2O Content = 0.07%

Ground Median Size = 1.2µm

Ground Surface Area = 4.3 m²/g

Na2O Content = 0.06%